KTI Applications

KTI has the perfect solution for all applications!

KTI – Pioneers in concrete cooling and concrete heating

Over the past decades, KTI has pioneered the field of concrete cooling technologies and continues to be the world’s number one in concrete cooling, thanks to the continuous technological developments. With the SAUTER brand, KTI also offers solutions in concrete heating.

It is necessary to cool or heat the concrete to control the temperature of the freshly mixed and poured concrete. Without a controlled cooling, stress cracks could appear within the concrete, which cause instability and fractures. Especially in dam, tunnel or bridge projects this would be an incalculable risk. On the other hand, winter concrete must be heated so that the curing process is guaranteed at all.

For this reason, regulations about the concrete pouring temperature are being formulated more precise since ever, so that even in moderate temperature zones, the issue of “temperature-controlled concrete” is becoming increasingly important.

KTI – Worldwide #1 in concrete cooling & heating

In an early stage, KTI recognized that there is a great demand in the concrete cooling and concrete heating market. In 2010, KTI-Plersch Kältetechnik GmbH aquired the business unit “Silo & Concrete Heating” of the formerly “Belimed Sauter AG” and in 2017 it was fully integrated into KTI. Since then, both divisions have been developing combined systems for concrete cooling and concrete heating.

Today, KTI offers its customers real “all-in-one solutions” for all types of concrete and temperature requirements, indepent of climate and outside temperature – and everything according to customer specifications. From now on a proper solution can be designed and offered according to every customer’s requirements for all temperature zones of the earth.

In connection with our own in-house developed calculation software we create the optimal solution for every concrete recipe and every concrete temperature. Our sound industry expertise allows us to advise you individually right from the beginning. Starting with a precise analysis of your requirements, the elaboration of a system concept up to the turnkey installation of the entire system, KTI offers you everything from a single source.

Efficient concrete cooling and concrete heating – made to measure

The demand of our customers to cool and heat economically and ecologically is sharply increased in recent years. Rising oil prices, a better understanding of the environment and higher demands on the quality of the concrete require better and more flexible cooling solutions and heating solutions for concrete batching plants.

Our portfolio comprises a wide range of equipment designed to cool or heat concrete: flake ice plants, plate ice plants, cold water plants, ice water plants, cold air plants as well as hot water plants or hot air plants. Through many years of experience, we can offer our customers an energetically efficient complete solution.

The strength of the concrete is closely related to the heating during curing (heat of hydration). For smaller constructions, the phenomenon is negligible, but very significant in mass concrete, e.g. for dam projects, or when the ambient tempreature is very high. The heat of hydration warms up the concrete by up to 25 °C and causes the concrete to expand.

After curing, the concrete cools down and the volume decreases, which creates tensions that lead to cracks in the concrete. Therefore, the mixing temperature must be lowered, so that a maximum temperature as specified by the planners is not exceeded during the curing process.

The required concrete pouring temperatures vary from site to site and country (from +7 °C to +30 °C maximum), hence there is always the need for a cooling system. Since investments and operating costs for a concrete cooling system can be high, it is important for KTI’s clients always to install an optimized system according to their needs.

Concrete Mixing Temperatures

Function of concrete mixing temperature in relation to water temperature and addition of ice.

Components of concrete cooling systems can vary depending on customer requirements, concrete mix design and/or required concrete temperatures. KTI supplies concrete cooling systems, which range from cold water systems or ice water systems up to ice plants and towards aggregate cooling systems. For very large projects, such as dams, KTI also offers the option of concrete post-cooling systems – cooling the concrete after casting.

1. Cold water plants or ice water plants

The addition of water for mixing the concrete is self-evident. At the same time, here is the first possibility to cool the concrete during the mixing process. The mixing water is pre-cooled to either 1°C or 4°C. With this a temperature reduction of about 11K can be achieved.

The Containerized Cold Water Plants of KTI (CCWP) cool water at an inlet temperature of +30 to +45 °C down to +4 °C. For lower concrete temperatures, KTI offers Containerized Ice Water Plants (CIWP), which cool water down to +1 °C. A CIWP is equipped with a special ice bank, which stores the ice water around a tube or plate evaporator. Of course, KTI offers also solutions that are designed for lower water inlet temperatures of +15 to +25 °C, such as those found in Europe or North America.

In addition to the cold water systems, KTI offers prefabricated and insulated cold water tanks. These can be installed beside or even under the cold water plants or ice water plants to save space and installation costs.

2. Flake ice plants or plate ice plants

By replacing cold water with the corresponding amount of ice a further cooling of the concrete can be achieved. In this case, a temperature reduction of another 14 °C is realised; the concrete can therefore be cooled down by a total of 25 °C.

KTI ice plants produce flake ice (FLIP) or plate ice (PLIP). A part of the cold water from the KTI cold water plants is used to produce the ice. All ice plants are pre-assembled and delivered in 40-ft-containers. A daily production of 100 tons of flake ice (FLIP) or 200 tons of plate ice (PLIP) is available in only one unit.

3. Combined plants - cold water & ice

A technical achievement of KTI are the combined plants that produce both cold water and flake ice. These are available in a single container with a daily Output up to 42 tons of ice and 176 m³ of cold water.

4. Ice storage

Just as important as the production of ice, is its storage. This allows a constant production of ice over the entire day and an immediate discharge and supply of the required amount of ice even during load peaks.

The ice storages of KTI can be used for both flake ice and plate ice and are available for up to 90 tons holding capacity. They are included with a fully automated ice rake system and automatic ice discharge system. Mobile Ice Storages (MIS) are manufactured in a heavy-duty steel frames and are available between 18 and 90 tonnes.

Semi-automatic ice storages (MIS-sa) can hold up to 23 tons and are installed in a 40-ft-container. The ice is discharged manually.

Furthermore, KTI manufactures bolted ice storages (MIS-b), which are prefabricated for quick assembly, but dismantled for transportation. This variant of ice storage is available up to a holding capacity of 250 tons.

5. Aggregate cooling

When cooling the concrete by adding cold water or even pure ice is not sufficient, the aggregates must be cooled before mixing. This can be done by both either using cold air or cooled water. Lowering the aggregate temperature by 2 °C allows the concrete temperature to be lowered by 1 °C. So the concrete can be cooled by at least another 10 °C only by aggregate cooling.

Aggregate cooling by cold air

Cooling the aggregates by air (CCAP), a large amount of cold air is blown through the silo. In particular, under difficult conditions, the cooling aggregates by cold air is an extremely effective method. In addition to saving energy, with cold air a much lower concrete temperature can be achieved than only adding cold water or ice, as this does not affect the maximum allowed water content.

The cold air flows through the silo from bottom to top and detracts heat of the aggregates. The silo can be fed with aggregates through the inlet at the top by conventional conveyor belts. As soon as the aggregates have arrived the silo outlet, they are cooled down depending on the dwell time in the silo and are ready for feeding the batching plant.

To distribute the air evenly, KTI has developed special nozzles that are permanently installed in the silo and ensure an optimal air flow around the units. Thus, an efficient utilization of the expended cooling capacity is guaranteed.

The cold air plants are built extremely compact and are available up to 1200 kW cooling capacity.

An installation of a cold air plant beside a concrete batching plant or aggregate silos can also be done later to upgrade the system. So, cold air plants offer a perfect complement or even an extension to an existing concrete cooling system.

Aggregate cooling by cold water

Aggregates can also be precooled by using cold water or ice water. This method represents a very fast method of aggregate cooling, does not require any modification of the silos and is independent of the size of the silo.

The aggregates are sprayed with cold water or ice water on a special conveyor belt, the wet belt, after the silo. Depending on the length of the conveyor belt and the corresponding dwell time of the Aggregates, they can be pre-cooled to very low temperatures. The returning water is “pre-cleaned” in a sedimentation basin and then cooled down again.

For the application of a wet belt, KTI has developed special cold water plants and ice water plants (CAC-w), which basically differ in the design from conventional cold water plants or ice water plants (CCWP, CIWP) from KTI. Special falling film coolers are used which are specially designed and produced for cooling contaminated water.

The cold water plants and ice water plants of KTI for aggregate pre-cooling with wet belt systems are available in different sizes and are especially designed and manufactured according to the requirements of our customers.

6. Post-Cooling

In the field of mass concrete, which is used for the construction of dams or other large structures, it is very often necessary to cool the concrete even after pouring. This makes it possible to dissipate the resulting heat of hydration from the interior of the structure and thus contributes to the achievement of the required concrete quality.

Pipelines are integrated into the concrete, through which cold or ice water flows and dissipates the heat. Here, the correct size and optimum distance of the pipes must be observed in order to dissipate the required amount of heat.

For post-cooling, the cold or ice water systems(CCWP, CIWP) of KTI need only be slightly modified. Due to the compact design of the systems, these can be shifted depending on the construction progress in order to cool various segments of the construction.

7. Accessories

Of course, KTI has developed appropriate accessories for all systems as an integral part of the portfolio. Likewise, the accessories are always found as one of the essential components of concrete cooling systems. By adding original KTI accessories to the KTI ice plant or ice storage, every system will be upgraded and even more efficient.

One of the most important accessory sets is in regards of ice transporation and ice weighing. The handling of ice requires a lot of experience, because the behavior of ice can only hardly be foreseen for certain circumstances. On the other hand, accurate weighing of ice is crucial to achieve the required concrete quality. Therefore, KTI has done intensive developments with various partners to provide customers with high quality and reliable products.

In addition to single or double screw conveyours, which are available in different lengths, and a suitable load cells, KTI offers equipment for pneumatic transportation of ice. This enables to transport the ice over longer distances. With so-called diverter valves, several stations can be supplied with ice.

Pouring concrete in wintry temperatures, a certain minimum temperature of concrete is usually stipulated. At air temperatures between +5 °C and -3 °C, the concrete temperature during the pouring process must be at least +5 °C; using cements with low heat of hydration even +10 °C are required. If the temperature is lower than -3 °C, a concrete temperature of +10 °C is obligatory.

This measure is necessary because concrete with +5 °C requires about twice the time for curing compared to +20 °C. When concrete reaches the -10 °C limit, the curing process stops completely. Similarly, frost shortly after pouring the concrete can cause blasting and thus microstructural defects.

The required concrete pouring temperatures vary from site to site and country (from +5 °C to +30 °C maximum), so there is always the need to use a suitable heating system. Since inestments and operating costs for a concrete heating system can be high, it is important for the client always to install an optimized system according to the needs.

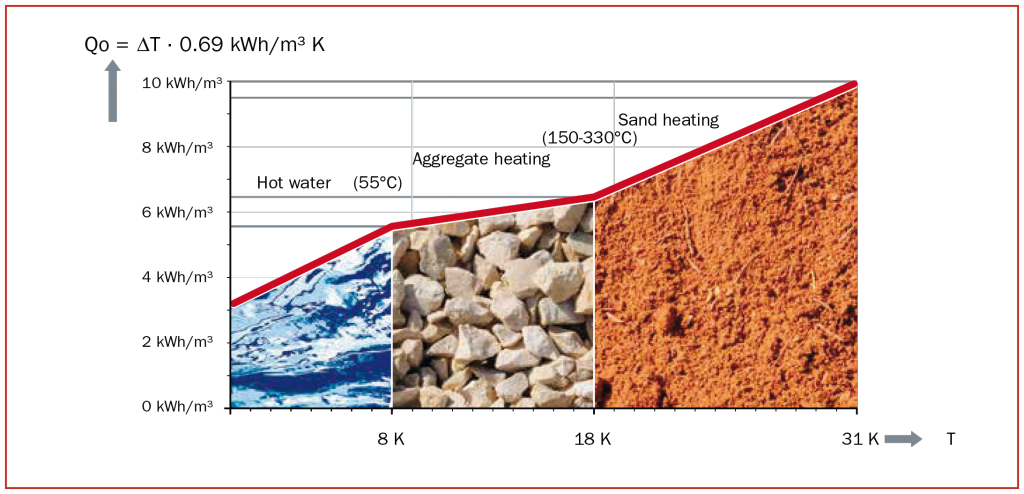

Similar to concrete cooling systems, the components of concrete heating systems can vary depending on customer requirements or concrete design and required concrete temperatures. KTI manufactures Sauter concrete heating systems, consisting of hot water systems, hot air systems or combined plants for hot water and hot air . For heating the concrete, there is always the possibility to use hot water for mixing the concrete: Under adverse circumstances, pre-heating the aggregates is a must.

Hot water station

KTI’s experience shows that hot mixing water at cold outside temperatures further improves the quality of the concrete. The Sauter Hot Water Station (HWS) from KTI offers a reliable supply of tempered mixing water to the concrete mixing plant tailored to the specific requirements.

The hot water station is available with capacities between 300 kW and 1,320 kW and thus meets the most common needs of KTI customers. With an oil, gas or combined burner an optimal and flexible solution is provided. Embedded circulation pumps and the standard anti-freeze heater guarantee operation also under harshest winter conditions.

Air heater

If winter concrete is required, the batching plant must be able to work safely even under lowest temperatures. Very high demands concerning the concrete, which must be delivered with temperatures up to +20 °C, require further measures than the sole addition of hot water. In order to avoid exceeding the cement-water ratio, the aggregates must be heated by hot air. Of course, Sauter Air Heaters (OLH) from KTI can be used as stand-alone alternatives for concrete heating.

For the above mentioned requirements, the air heater (OLH) is the ideal solution. Whether for heating the aggregates, simply “keeping them warm” or for minimal heating rooms, the OLH offers the opportunity for flexible use.

The Sauter Air Heaters (OLH) are available in three different sizes (210 kW, 380 kW, 1000 kW) and cover usual needs of Sauter customers. With an oil, gas or combined burner an optimal and flexible solution is provided. Of course, the OLH can be delivered fully preinstalled and containerized. Often, hot air systems (OLH) and hot water systems (HWS) are installed as a combination in a joint standard 20-ft container.

Combined plants (TURBO / BOOSTER)

With ever-increasing demands on the concrete and at the same time very adverse weather conditions, such as those found in Canada, Scandinavia or Russia, high performance systems are needed to reliably supply the required heating energy induced into the concrete. The combined plants offer the advantage of producing heat outputs up to 1500 kW as well as heating hot water and hot air with just a single burner.

The Sauter combined plants from KTI are basically divided into two categories, which are to be selected according to customer requirements and installation situation:

The new Sauter TURBO – highly effective and reliable

The TURBO simultaneously produces hot water and hot air with a single burner and provides 100% energy utilization. This is realized by inducing any energy generated by the burner directly into the mixing water or as hot gas-air mixture in the aggregate silos or sand silos.

In the product family of the TURBO plants, three types are available: the TURBO Splash with focus on hot water heating (70%), the TURBO Dragon with focus on hot air generation (75%) and the TURBO Switch, which allows to choose one of both options depending on the situation.

All TURBO systems offer the STEAM function, which generates steam by injecting water into the hot gas stream. This can be used to rapidly defrost aggregates or sand.

Highest efficiency and emission-free air with the Sauter BOOSTER

The Sauter BOOSTER, like the TURBO, generates both hot water and hot air. However, the BOOSTER strictly separates the exhaust gases and the hot air flow. This offers the user the advantage that no combustion gases can accumulate in the silos and in closed or isolated rooms, as the exhaust gases are led separately directly into the open air via a chimney.

The BOOSTER can be optionally equipped with an efficiency package, which reduces the exhaust gas temperature to about +70 °C via a special heat exchanger. As the result, the efficiency is increased up to about 97%.

Furthermore, a part of the heat can be used for heating rooms for filling the water tanks of truck mixers with hot water.

Mine Cooling – Safety through KTI’s reliable and efficient solutions

With containerized Plate Ice Plants (PLIP) and the Underground Chiller (UC), KTI has created a flexible and highly efficient way to cool deep mines. This guarantees the operation of the mine even under the adverse underground conditions and keep the miners’ working environment at the recommended ambient temperature. With this, KTI is a pioneer in replacing the traditional large-scale refrigeration systems and the adherent costs with modular, “growing-when-necessary” refrigeration systems.

Currently, the mining industry faces three major challenges worldwide: cost-cutting measures, increasing efficiency, sustainability. With new technologies, mining companies have more and more opportunities to recover ore deposits at greater depths. As a result, there is a growing demand for innovative methods to support these projects.

Whether mines for gold, copper or platinum – at depths of 2000 m and more below the surface, ambient temperatures of +60 °C or higher are common. Necessary excavation activities generate additional heat, which impedes the working conditions of the miners. An essential prerequisite is that the working areas of miners, who work underground for longer periods, must be cooled to the recommended ambient temperature.

Surface Cooling with KTI’s Plate Ice Plants (PLIP)

The required refrigeration capacities for cooling deep mines are considerable and can easily exceed 2000 tons of ice per day.

For this field of application, KTI has developed special Plate Ice Plants (PLIP) with a capacity of up to 200 tons per day. The ice cooling systems are modular and can be expanded with the growing demand for ice needed. KTI’s Plate Ice Plants operate at the optimum operating point and offer way more cooling capacity than conventional chiller systems. The reason is, that one kilogram of ice absorbs much more energy than one liter of cold water, so ice systems require more than 80% less pump energy for water recirculation. Thus, annual power savings of several million kWh can be achieved.

The systems are installed and operated on the surface. The produced ice is transported down through the mine shaft, where it is collected in so-called underground melt dams to provide the required cooling capacity. Both the ambient air and the equipment can be supplied with this cooling power.

Underground Chiller (UC) – Robust against harsh environments

In addition to the ice cooling systems, KTI has developed Underground Chillers (UC) with cooling capacities of up to 500 kW in one unit. The chillers are designed for the adverse conditions and heavy-duty demands in the mining industry. The special design allows an application underground and an easy transport through the mine shaft to the place of operation.

Make the most out of your catch

One of the biggest challenges in the fish and seafood industry is the controlled cooling of freshly caught fish or seafood. Proper cooling directly after harvesting is the key factor for storing and transporting fish or other seafood over longer distances without losing quality and freshness. The shelf life depends largely on the speed of cooling the harvest to about 0°C. The most effective way to achieve this is to store the fish or seafood on ice.

The ice systems from KTI offer very high flexibility, because of their modular design and customization to the needs of KTI’s customers. Due to the modular structure, the systems can be easily expanded and grow with the requirements. Thus, KTI offers solutions which, in addition to high efficiency, also bring further economic advantages. Adverse weather conditions or power outages can not affect the cooling of fish or seafood by ice. It is also a very safe way to maintain the cold chain – from catch to sale – to avoid losses from spoiled goods.

Cooling the harvest solely by cold air damages the catch and dries it out. Ice keeps it fresh, moist, shiny, appetizing, thus maintaining a good market price.

KTI ice systems for a sustainable fisheries management

The extensive range of KTI ice plants is equally suitable for fishermen, fishmongers, fish processors and fish farms. The combination with our refrigerated mobile ice storage makes it possible to store large quantities of ice, which can be retrieved at high speed on demand. Thus, the fishing fleets are quickly well prepared to be able for taking off.

KTI’s ice plants produce various types of ice, such as flake ice, plate ice, flow-ice or block ice. Depending on the application the most appropriate type of ice has to be selected, while each type has its own advantages. However, all KTI plants have one thing in common: they provide the best ice quality to optimally and rapidly cool down the caught fish or seafood.

All ice systems are installed inside containers and can be easily transported as well as quickly installed on site. They are easy to place on the wharf to load the ice directly into boats. KTI provides ice handling equipment for storing, transporting and weighing the ice.

Flake Ice – Ideal For Rapid Fish Cooling

Flake ice cools the fish very fast, thanks to its large specific cooling surface. Flake ice is continuously produced without defrost cycles, which makes it dry and subcooled. This has two advantages: better cooling performance and easier ice handling.

KTI Flake Ice Plants (FLIP) are available in different sizes, ranging from 20 to 100 tons of ice production per unit per day. With their modular design, they can easily be combined to produce up to 200 tons of ice per day feeding one joint KTI Mobile Ice Storage (MIS).

Plate Ice – Melts Slowly

Plate ice is a thicker ice that melts slowly due to its lower surface area compared to flake ice. If there are no refrigerated ice storages available, it can be stored well in uncooled containers and transported over longer periods without major melting losses.

KTI Plate Ice Plants (PLIP) are available in capacities of 40 to 200 tons of ice production per day per unit. The engineers of KTI have developed a very efficient system for ice production, which achieves significant savings in power consumption.

Storing the plate ice with KTI’s specially modified Mobile Ice Storages (MIS) is possible. Also, the ice transportation was further developed and realized by KTI.

Block Ice – Long-Lasting Cooling Source

The surface of an ice block for heat exchange is limited. Under tropical conditions block ice can be transported uncooled to the consumer without almost no melt loss. This provides an efficient way of storing refrigeration energy when no power supply is available.

The Block Ice Plants (MBIP) of KTI are available between 10 to 50 tons of ice production per day. An ice block weighs about 25 kg, which is an optimal size for further processing. Of course, other sizes of ice blocks are available as well.

The ice storage(MIS, MIS-b) can be used very well for storing block ice, as well.

Mobile Cold Stores – Instant Cooling Mobile

The Mobile Cold Stores (MCS) are developed by KTI especially for the storage of food and adapted to the difficult requirements. The cold stores have a storage capacity of more than 200 m³ and are divided into two temperature zones, which allow to store food at +5 °C and -20 °C.

KTI’s Mobile Cold Stores are a perfect complement to all KTI ice systems. Featuring a modification developed by KTI, they can serve as a foundation for the ice storage. With this, KTI provides customers with holistic solutions for cooling and storing fish and seafood.

Efficient refrigeration for food and beverages along the entire value chain

For the food industry, proper cooling is one of the most important factors for increasing or at least maintaining a company’s profitability. Companies involved in the production of products at all stages – from harvesting to further processing, packaging and delivery – must take great care to ensure that suitable technologies are used. In addition to unwanted costs, spoiled products also cause large amounts of waste.

The use of ice - more than just frozen water

When fruits and vegetables are processed, ice can be used to cool or actually freeze the product. In any case, it is an extremely flexible and versatile solution for preserving products. The ice cools the product to just slightly above 0 °C and thus avoids freezing of the sensitive goods. As the ice cools the fresh vegetables, the melted ice water evaporates, keeping the ambient air humid. The ice ensures the perfect balance between humidity and temperature, thus preserving the water content and freshness of the products.

In the field of baked goods, ice already plays an important role in the preparation of the dough. Smaller amounts of flake ice are added to the kneader to allow accurate temperature control of each batch below +20 °C. Thanks to the large surface area of flake ice, a rapid cooling is enforced which reliably prevents secondary fermentation of lactic acid and butyric acid, undesired growth of bacteria, inconsistent dough texture, unpleasant odor and pungent taste.

In the meat processing industry, flake ice, also in combination with ice water, is excellent for cooling but also for the actual process. Due to its ability to inhibit bacterial growth, the addition of flake ice into the meat cutter is useful for producing sausages or pies.

Likewise, the use of cold water or ice water in the slaughter of poultry, in order to easily handle the critical cooling phase in this process. To reduce the core temperature, the poultry is dipped into ice water or cold water after slaughtered and the temperature is lowered from +40 °C to below +4 °C.

In addition to Cold Water Plant (CCWP) or Ice Water Plants (CIWP), KTI has different ice plants available – flake ice (FLIP), plate ice (PLIP) and block ice (MBIP). Together with an KTI ice storage (MIS, MIS-b), the ice can be stored for longer periods and delivered in the desired quantity just on request. Depending on the needs of the customers and the application, the different plants of KTI are combined to a holistic refrigeration solution.

Highly efficient chillers for the beverage industry

With a constantly growing variety and quantity of beverages – from water to soft drinks to beer – the complexity in their production and thus also the requirements for efficient cooling increases.

Additional consumers such as stretch blow molding machines for the production of PET bottles or other machines must be cooled continuously. New ingredients and innovative manufacturing processes require further options to cool the fresh drinks before, during and after bottling.

At the same time, the focus is on energy saving, opening the potential to minimize production costs for the best competitive advantage.

KTI water chillers offer a highly efficient solution that is individually designed and optimized according to the given requirements. Of course, the engineers at KTI take into account the customer’s specifications, requirements and wishes – the focus is always on saving of cooling energy and, at the same time, high flexibility for the customer.

The savings made with KTI chillers amortize your system in a short period. Simple installation, easy operation of the system and the highest quality make the KTI solution to a reliable solution.

All KTI systems are available with ammonia (R717) as refrigerant, making the system even more efficient, thus an environmentally friendly solution.

Mobile storing of food for a maximum of flexibility

Ensuring appropriate cooling for food is a critical success factor. However, cooled facilities to store goods are the bottlenecks in many cases. Further, it can be the requirement that certain products must be stored in strictly separated rooms to avoid contact with other goods. Whether in food processing companies or logistics companies, which require cooled storage capacities, KTI’s Mobile Cold Stores (MCS) can be used wherever there is a need to quickly and flexibly create a cooling solution for products.

With the Mobile Cold Stores (MCS), KTI has created a product that creates a refrigerated space where you need it – without any hassle and expense of planning or expanding existing buildings. The applied technology is based on KTI’s proven Mobile Ice Storages (MIS) have been used worldwide for decades.

Mobile Cold Stores can be used as standalone refrigerated space or as a building extension. Thanks to the specially designed steel construction, it is possible to put several mobile cold stores on top of each other, thus also connecting cold rooms on different floors. Of course, the access with smaller pallet jacks is guaranteed to ensure easy loading and unloading of pallets.

Cooling exothermic reactions with KTI ice systems for pigments production

Dyes and pigments are used in the plastics industry, dyestuff industry and textile industry, but also in many other industries. During production, these are synthesized in reactors, where an exothermic chemical reaction is taking place.

The resulting very high temperatures must be strictly controlled in order to comply with safety and quality regulations to prevent failed reactions.

This can be done with flake ice. KTI Flake Ice Plants (FLIP) produce dry ice with very good heat absorption properties in compliance with environmental, health and safety guidelines.

KTI flake ice plants (FLIP) for the control of exothermic reactions

KTI’s Flake Ice Plants (FLIP) are built according to the demanding electrical and safety standards of the chemical industry and will be supplied completely from a single source. This includes the design of pressure vessels and ice makers in accordance with the Pressure Vessel Directive 97/23/CE, explosion proof motors and CE compliant electrical installation. KTI can deliver ice capacities from 20 to 100 tons of ice production per day installed in only one unit. Of course, these can be easily extended, should the need for more ice occur.

Particular attention is paid to energy efficiency. KTI uses environmentally friendly refrigerants such as ammonia (R717) and has optimized the plant design.

The flake ice plants continuously feed the KTI Mobile Ice Storage (MIS, MIS-b) with flake ice. The ice is temporarily stored and can be discharged immediately when required. The ice is transported fully automatically from the ice storage to the vats.

Pneumatic conveying systems allow to transport the ice to several remote locations at high delivery rates. Weighing systems can be integrated for the exact dosage of ice.

Special Solutions for Industrial Refrigeration – Professional design, planning and manufacturing from a single source

A reliable supply of cooling power in the form of cold water or ice is one of the critical factors for most applications of KTI’s customers. Coupled with this, the requirements for an industrial refrigeration system from KTI are high system availability, precise production and optimized energy consumption.

With more than 30 years of experience in the design and manufacturing of refrigeration systems, KTI-Plersch has a fundamental knowledge and expertise. By supplying different industries with refrigeration equipment, KTI knows as a competent partner, the specific needs of its customers in the respective industries and can provide the best advice through the valuable know-how.

KTI has been pursuing a consistent consulting concept since its founding – beginning with a profound analysis of the individual requirements, a specific concept and professional advice of the customers up to the production and commissioning of the plants.

Your requirement is the challenge of our engineers

The state-of-the-art planning tools, some of which have been developed in-house, combined with the extensive expertise in the field of industrial refrigeration, form the basis of KTI. Together with our customers, this creates refrigeration solutions that are individually tailored to the wishes and needs of the customers.

Already during the offer preparation the experts of KTI get in touch with our customers, in order to determine the exact need. Our sales and technical staff help our customers to find the best solution. Often KTI has been able to find alternative solutions for the customer.

Design-to-cost right from beginning

Taking into account all costs of the different product lifecycle phases, plays a major role in all projects. KTI supports its customers from the beginning to develop the most cost-effective solution. Since sustainability is one of our core values, this aspect already plays an important role in the plant design. Using different calculation tools, our engineers also optimize the running costs in addition to the investment costs. Thus, KTI already supports all customers in concept development and budgeting.